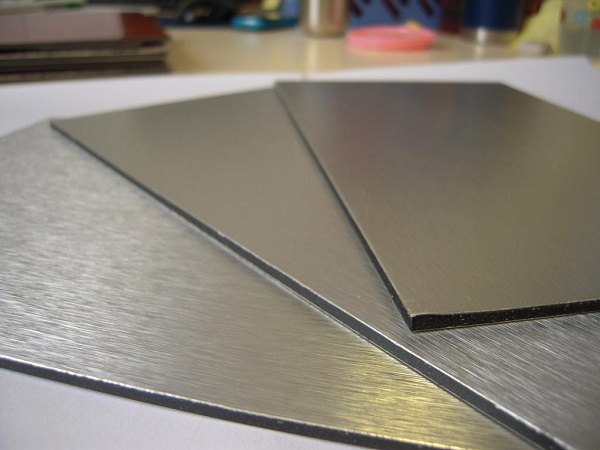

Brushed aluminum composite panel

The alloy face plate of aluminum composite material USA classic surface wiredrawing processing, common is wiredrawing product of gold and silver wiredrawing, bring different vision to enjoy to the person. The front side of the aluminum plate has been drawn, the surface of the front side of the aluminum plate is covered with a protective film that can be removed, and the surface of the back of the aluminum plate is chemically pretreated aluminum surface corrosion-resistant or pre-laminated with anticorrosive poly- Main Uses: mainly used for interior decoration, exhibition building and so on.

Sandwich panel

Specifications and dimensions of composite aluminum material:

1220 × (wide) × 2440 (long) × 2.5 (thick) mm Aluminum thickness: 0.08mm

1220 × (wide) × 2440 (long) × 3 (thick) mm Aluminum Thickness: 0.08 ---- 0.21mm

1220 × (width) × 2440 (long) × 4 (thickness) mm Aluminum thickness: 0.12 ---- 0.50 mm

. Non-standard size will be determined by both parties through negotiation according to customers' requirements

Wall panels composed of external wall aluminum: aluminum thickness has five specifications

: 0.30 mm, 0.35 mm, 0.40 mm, 0.45 mm, 0.50 mm.

② aluminum interior wall - composite plate series of plastic: aluminum thickness has five specifications

: 0.30mm, 0.21mm, 0.18mm, 0.15mm, 0.12mm.

③ fire-resistant aluminum - composite plate series of plastic: aluminum thickness has six specifications

: 0.25mm, 0.30mm, 0.35mm, 0.40mm, 0.45mm, 0.50mm.The plate thickness can be achieved

3mm ~ 6mm;

DER-ACP is a professional ACP panel manufacturer and supplier in China with more than 20 years' experience. We are located in Wenzhou, Zhejiang province. Now we are exporting to over 60 countries worldwide.

Copyright © DERACP All Rights Reserved. Links:TPU fabric