The difference between aluminium composite panels and colour steel panels.

1.Material

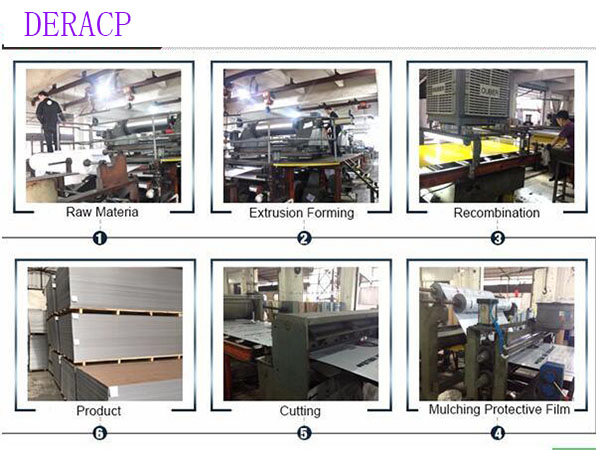

2.Production process

3. Thickness

4. Surface condition

5. Product structure

6. Use

The traditional coating of colour steel sheets is divided into several categories, the most high-grade is the fluorocarbon coating, which can be anti-corrosive for almost 20 years. It is generally distributed from steel mills in rolls to various places. The colour steel plate we often see is a processed plate, with a thickness of about 50~100mm, which is made up of a filler in the middle and a colour steel plate on both sides. In this case, the colour plate thickness is available in different thicknesses such as 0.4mm, 0.5mm and 0.6mm, and the middle layer can be polyurethane, rock wool or foam. As there are special profiles, the construction of a plant constructed with colour-coated steel plates is fast (such as the Xiaotangshan Hospital during SARS), but the strength is low. The substrates of colour coated steel sheets are cold rolled substrates, hot dip galvanised substrates and electro galvanised substrates. The coating types can be divided into poly, silicon modified poly, bi-poly difluoroethylene and plastisol. The surface state of colour coated steel sheets can be divided into, coated, embossed and printed sheets.

Colour coated steel plate is widely used in the construction of appliances and transportation and other industries, for the construction industry is mainly used for steel structure plant, airport, warehouse and refrigeration and other industrial and commercial buildings such as roof walls and doors, civil buildings using colour steel plate is less.

Aluminium-plastic, i.e. aluminium-plastic composite panel, is a composite material processed on special aluminium-plastic production equipment using chemically treated painted aluminium sheets as the surface material and polyethylene plastic as the core material.

It is the adoption of high-purity aluminium sheet and PE polyethylene resin, subverted low temperature and high pressure one-time composition of composite decorative panels, the internal subverted special process of spraying plastic, bright and rich colours, long-lasting application of non-fading. If the central sandwich of the usual type of aluminium-plastic composite panel is PVC (polyvinyl chloride), the composite panel will produce harmless chlorine gas when it is extinguished and heated, and the central sandwich of the fireproof type of aluminium-plastic composite panel is FR (fireproof plastic).

The unique properties of the aluminium composite panel itself determine its wide range of uses: it can be used for building facades, curtain wall panels, renovation of old buildings, indoor wall and ceiling decoration, advertising signs, display stands, purification and dust control projects.

Aluminium composite panels are important for paving the outside of furniture and structures with larger areas, women's-parlour TV backdrops, columns or outdoor structures, where the lower layer needs to be manufactured with wood core boards and then coated with public glue for pasting. Excellent aluminium composite panels have a layer of film outside, to be uncovered after the construction is completed, the panels should be completely flat, sharp and neat corners, without any bending deformation.

Home decoration with aluminum composite panel as usual applied in the restaurant, kitchen, bathroom and room heating cover, insulation and other appearance, construction, first of all, the plate base to dry flat, good with multi-layer board, joinery board to do the bottom layer, to avoid cracking deformation. Secondly, in the pasting of aluminum plastic board, we should pay attention to the coating glue must be average, to be strong glue diluent evaporated with hand touch not sticky hands can be pasted, with wooden hammer knocking compaction. Thirdly, the aluminium composite panel should be divided into many pieces according to the plan. Not suitable for the whole sheet or large area application, otherwise it is easy to cause the drum open glue. Fourth, the aluminum composite panel seam mouth as usual with glass glue seal, request glass glue injection seal must be average full, dry to clear the outside clean, so that the line thickness equal.

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel