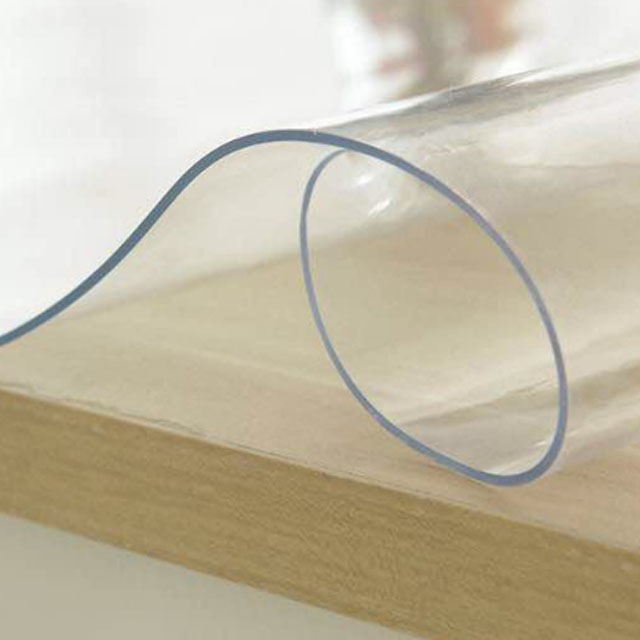

Clear PVC film is mainly used for curtains, table cloth, high-grade products packaging, handbags, bags, stationery, electrical tape film, rain coat film and daily necessities. DERACP new material suppliers compete specifications films with the most reasonable price.

| Material | PVC |

| Product name | Super clear pvc sheet/ clear pvc / transparent pvc film |

| Type | Stretch film super clear / laminated super clear |

| Feature | Water soluble |

| Hardness | Soft |

| Transparency | super clear transparent |

| Thickness | 0.07mm-3.2mm |

| Density | 1.36-2.4 |

| Color | Light blue/purple/ white etc |

| Tensile strength | MPA > 52 |

| Impact strength | KJ/M2 > 5 |

| Vicat softening point | 75 oC |

| PHR | 30-80 |

| Certification | EN71-2; EN71-3; Reach standard ; Anti-UV; Anti-Cold ; Anri static ; Fire retardent |

| Packing | PE foam or kraft paper with clear film or color film |

DERACP soft super clear pvc film roll

1.High chemical stability, fine anti-fire, super-transparent.

2.High UV stabilized, good mechanical properties, high hardness and strength

3.The sheet also has well aging resistance, good self extinguishing property and reliable insulativity.

4 .Moreover the sheet is waterproof and has very good smooth surface, and is non deformable.

Classification of pvc ultra-permeable membrane:

PVC super-permeable membrane can be divided into PVC soft film and PVC hard film. During this period, hard PVC accounts for about 2/3 of the market, and soft PVC accounts for 1/3. Soft PVC is generally used for the surface layer of floors, ceilings and leather, but because soft PVC contains softeners (this is also the difference between soft PVC and hard PVC), it becomes brittle and difficult to preserve, so its scope of application is limited. Hard PVC does not contain softeners, so it has good flexibility, easy to form, not brittle, non-toxic and non-polluting, and has a long storage time, so it has great development and application value. Hereinafter referred to as PVC.

The use of pvc film:

The essence of PVC is a vacuum blister film, which is used for surface packaging of various types of panels, so it is also known as decorative film, adhesive film, and is used in many tasks such as building materials, packaging, medicine and so on. During this period, construction materials accounted for the largest proportion, accounting for 60%, followed by packaging, as well as several other small-scale applications.

The difference between PVC film and general adhesive film:

The general adhesive film is directly glued on the surface of the board at room temperature, so after one or two years, the film will simply drop. The PVC film is attached to the surface of the board at a high temperature of 110 degrees using a special vacuum film pressing machine, so it is not easy to fall. Although PVC film has excellent quality assurance, some people may say that PVC is a chemical product after all, it is not comparable to natural materials, it can not clean the toxicity and odor, and it will inevitably cause damage to the environment. Actually, this is not the case. This is because the material of PVC film produced in Germany is specially refined, and the toxic substances are completely extracted. Therefore, PVC is completely non-toxic and tasteless, and has no effect on human skin or respiratory system. For people who are allergic to wood and paint, furniture or kitchen utensils packed with PVC film are very suitable. By using PVC film as a decorative film, people can use a large number of medium-density board, particle board, plywood and fiberboard to reduce the use of wood.

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel