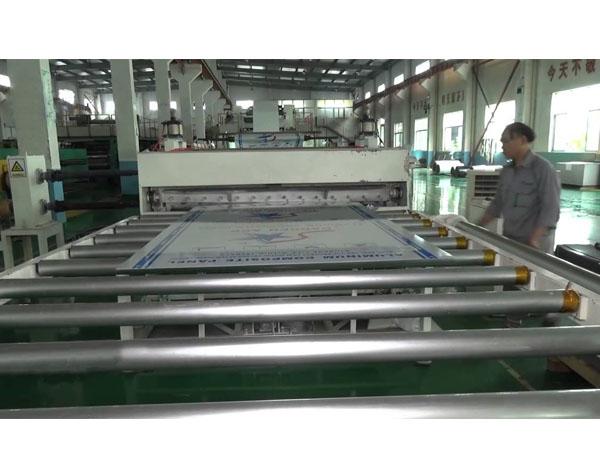

The production process ,such as cold composite method, thermal composite method, continuous composite method and intermittent composite method, is used for Aluminium Composite Sheet , according to plastic core and both -side panels.

First, to cleaning the aluminum coil is essential part in production . The surface is coated with lubricants and anti-oxidants, and dust is attached during transportation, affecting its adhesion.

Second ,a dense chemical protective film is formed on the surface of coils to improve the oxidation resistance and prolong the life ,after cleaning and chemical treatment.

Regular process for cleaning : aluminum coil→spray degreasing →water washing→neutralization→chemical treatment→water washing→drying→cooling→winding.

Third ,The cleaned aluminum coil is put into to a coater , while painted a high performance fluorocarbon resin on the surface.

The process flow : aluminum coil→feeding→coating fluorocarbon coating→hot air circulation baking paint→cooling→filming→cutting→winding.

Fourth , The panels of the exterior ACP panel coated with two layers of paint and primer so that the topcoat of the façade is a highly weather-resistant fluorocarbon resin coating, namely polyvinylidene fluoride (PVDF) featuring excellent UV resistance and environmental pollution . That keeps the surface beautiful.

The surface of ACP sheet have not only the metal color , but also the beautiful marble pattern types. Fluorocarbon coated are usually applied to aluminum coils by roll coating and then baked at elevated temperatures to dry them.

The equipment is continuous to produce , first primed, then top coated, and lastly, coated with a surface varnish. The total thickness of the three-layer paint is 30μm. Each layer of paint needs to be baked at 200 °C for about 60 seconds until it dry

Fifth , After the oven is baked, it is quickly cooled by an air cooler. The interior wall paint can be made of epoxy resin, polyester resin and acrylic resin. After the primer, topcoat, and surface varnish are coated, immediately apply a PE protective film on the surface of the coating to avoid scratching the surface during subsequent processing, transportation, and installation.

The protective film is self-adhesive and can be removed after installation. The aluminum coil coated with fluorocarbon resin can enter the process of compounding with the plastic core material.The plastic core material is also essential three layers, with PE plastic in the middle and adhesive on both sides. PE sheets and adhesives can be produced separately or by three-layer co- extrusion.

the three-layer co-extruded sheet with the structure of adhesive is step to be produced, and then combined with the upper and lower aluminum sheets. 0.15mm is available in thickness with aluminum panel on both sides,and 3~5mm in the core layer , 4~6mm in total thickness . Finally ,a whole panel is cut into 1220x2440mm .

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel