Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Preparation method of fireproof core material for aluminum-plastic composite panel, including the following steps: (1) preparation of raw materials; (2) granulation of fireproof core material; (3) pressing into panels; (4) testing of finished products. The process of the invention is simple, the quality is stable and controllable, and the fireproof core material adopts nano-level inorganic flame retardant with reasonable formulation, which improves the compatibility between the interface of flame retardant and resin, thus improving the peel strength and tensile performance of the finished aluminum-plastic composite panel.

Halogen-free flame retardant and fireproof aluminum composite panel acp B grade core material

This product is made of polyethylene as the main raw material, adding environmental protection flame retardant, and using continuous activation equipment to fine compound coupling treatment on its surface, then adding flame retardant synergist and other additives, and extruding and granulating through full mixing and plasticizing. The material has excellent flame retardant and smoke suppressing property and carbon forming and drip inhibiting property, and also has good mechanical property and extrusion processing property.

Halogen-free flame retardant and fireproof aluminum composite board B grade core material is off-white solid particles, which has the advantages of environmental protection, light weight, easy processing, etc. It is in line with the development trend of all flame retardant materials and can meet the requirements of the building decoration industry. It has already reached the national requirements for fire retardant building decoration materials, and the fire grade can reach B1.

Product characteristics 1、The product is mainly used in the production of fireproof aluminum-plastic board, as the plastic core material of fireproof aluminum-plastic board, it has the advantages of good fireproof performance, good toughness, good bonding performance with polymer film, easy processing, etc. 2、The fireproof aluminum composite panel produced by using this core material, in addition to having excellent fireproof performance and reaching the national flame-retardant class B standard, also solves the problem of weak mechanical properties at the folded edge when the aluminum composite panel is installed. 3、The mechanical strength, fatigue resistance and corrosion resistance of the folded edge are greatly improved, and it has high peeling strength, which can greatly widen the application field of aluminum composite panel sheet.

l You may also want to know about aluminum composite materials from DERACP

|

Coating |

PE / PVDF/ FEVE/ NANO |

|

Core |

LDPE/Fireproof |

|

Length |

Customized |

|

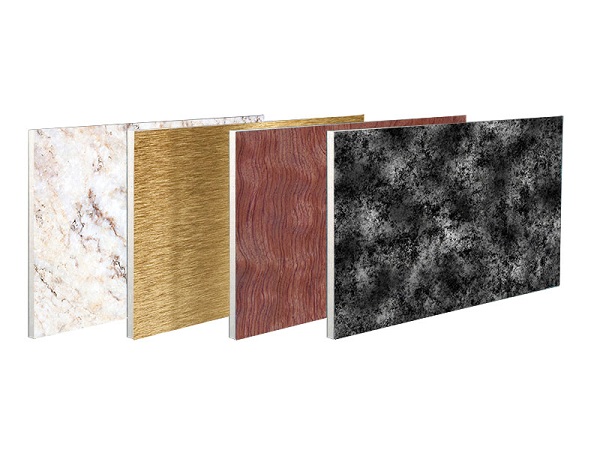

Color |

Solid / Metallic / Marble / Wooden / Brush / Glossy/ Mirror, custom |

|

MOQ |

600 SQM each size per color |

|

Brand / OEM |

DERACP or Customized |

|

Delivery |

15 day after deposit received and color confirmed |

|

Payment Terms |

T/T / L/C / Western Union / Paypal |

|

Packing |

Wooden Package or bulk loading |

Application:

1、aluminum composite panels acp wall cladding

2, the old building exterior wall modification and renovation. wall cladding sheets aluminum composite panel

3、Balconies, equipment units acp , indoor compartments acm .

4、acp sheet for advertising sign board, display stand.

5、Interior wall decorative acp panels,ACP ceilings, advertising signs ACP panels.

l About DERACP

DERACP found in 2000 ,we are specialized in manufacturing building materials, such as Aluminum Corrugated Composite Panel (ACCP) , Aluminum Composite Panel (ACP), fire rated aluminum composite panels ,Color coated Aluminum Coil etc.The factory located in Wenzhou, Zhejiang Province, China, all transportation options are convenience to the factory.It's easy to get to the airport and port. Our factory covers an area of 15,000 square meters , the warehouse covers an area of 5000 square meters and has six production lines. We have the best aluminum leather suppliers and adhesive suppliers .

We currently have over 300 employees including 8 engineers, all of them are participate in the composite materials development more than 10 years . Our factory is ISO9001:2008 certified in quality management systems, ISO14001 :2004 certified in environmental management systems and SAS 18001 certified for Occupational Health and Safety and BSCI(Business Social Compliance Initiative) certified. Our products also have passed SGS, CE(attestation of European Union), and CTC(China Building Material Certification).

If you have any questions, contact me, please.

Contact: Kerry zhu

Whatsapp & WeChat : +86 130 4067 0248

Email : kerry@der-acp.com

You’ll get my response within 24 hours.

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel

Building construction materials for interior & exterior aluminum composite panel