Aluminum composite panel is made of multi-layer materials, the upper and lower layer is high purity aluminum alloy panel, the middle is non-toxic low density polyethylene (PE) core panel, and its front side is also pasted with a protective film. For outdoor, the front side of the aluminum composite panel is coated with fluorocarbon resin (PVDF), and for indoor, the front side can be coated with non-fluorocarbon resin.

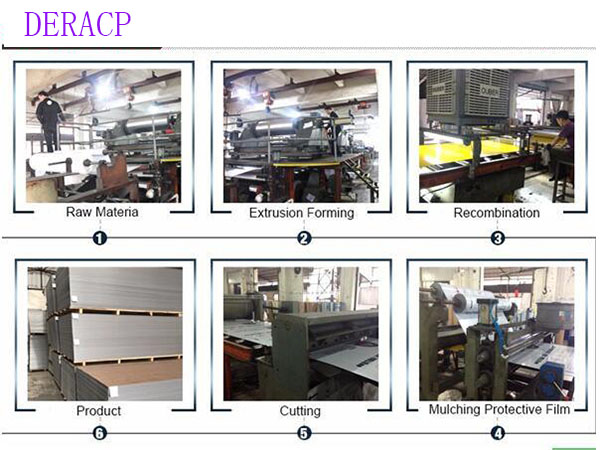

There are various production processes of aluminum composite panels(ACP), which can be divided into cold and hot compounding according to the compounding process of plastic core panels and two-sided aluminum panels; they can also be divided into

It can also be divided into continuous compounding and intermittent compounding. The first process of producing aluminum composite panel is to clean the aluminum coil. Aluminum coil in the production process because of the need, the surface are Coated with lubricants and anti-oxidants, in transport will also be attached to some dirt, these will affect its bonding, so it must be cleaned.

Aluminum coil After cleaning and chemical treatment, the surface will produce a layer of dense chemical protection film; this layer of chemical film can improve the resistance to oxidation of aluminum coils and

This layer of chemical film can improve the resistance to oxidation and extend the life of the paint film.

The general process of cleaning is as follows: aluminum coil → spray degreasing → water washing → neutralization → chemical treatment → water washing → drying → cooling → winding.

The cleaned aluminum coil is sent to the coating machine to coat the outer surface of the aluminum coil with high-function fluorocarbon resin.

The process flow is as follows: aluminum coil → feeding Material → coating fluorocarbon coating → hot air cycle baking paint → cooling → laminating → cutting → winding external wall aluminum composite panel panels to be coated with two layers of paint and primer each. The top coat of the exterior wall panel is a fluorocarbon resin coating with extremely high weather resistance, namely polyvinylidene fluoride (PVDF), whose excellent anti-UV function and resistance to environmental pollution make the surface of the protected aluminum coil maintain a brilliant color. The surface of aluminum composite panel can not only have the brilliance of metal, but also can have brocade marble pattern and color. Fluorocarbon coating is usually applied to the aluminum coil by roller coating method, and then dried by high temperature baking. The equipment is continuous production, first coated with primer, then top coat, and finally coated with surface varnish. The total thickness of the three layers of paint reaches 30μm, and each layer of paint needs to be baked above 200 ℃ for about 60s to dry, and then cooled rapidly by air cooler after leaving the baking box. Epoxy resin, polyester resin and acrylic resin can be used for interior wall panel paint. After the primer, top coat and surface varnish are coated, a PE protective film is immediately applied to the surface of the coating layer to avoid the surface coating from being scratched during later processing and smooth transportation and installation. The protective film is self-adhesive and can be removed after installation. The aluminum coil coated with fluorocarbon resin can enter the process of lamination with plastic core material. The plastic core is essentially three layers, with PE plastic in the middle and adhesive on both sides, and PE sheet and adhesive can be produced separately or in a three-layer co-extrusion method. The structure of the adhesive/PE/adhesive three-layer co-extruded sheet is produced first, and then it is compounded with the upper and lower two layers of aluminum sheet, the compounded aluminum-plastic composite sheet is 0.15mm thick on both sides, the core layer is 3~5mm, and the total thickness is 4~6mm. Finally, the sheet is cut into 1220mm×2440mm size.

l You may also want to know about aluminum composite materials

|

Coating |

PE / PVDF/ FEVE/ NANO |

|

Core |

LDPE/Fireproof |

|

Length |

Customized |

|

Color |

Solid / Metallic / Marble / Wooden / Brush / Glossy/ Mirror, custom |

|

MOQ |

600 SQM each size per color |

|

Brand / OEM |

DERACP or Customized |

|

Delivery |

15 day after deposit received and color confirmed |

|

Payment Terms |

T/T / L/C / Western Union / Paypal |

|

Packing |

Wooden Package or bulk loading |

l About DERACP

DERACP found in 2000 ,we are specialized in manufacturing building materials, such as Aluminum Corrugated Composite Panel (ACCP) , Aluminum Composite Panel (ACP) ,Color coated Aluminum Coil etc.The factory located in Wenzhou, Zhejiang Province, China, all transportation options are convenience to the factory.It's easy to get to the airport and port. Our factory covers an area of 15,000 square meters , the warehouse covers an area of 5000 square meters and has six production lines. We have the best aluminum leather suppliers and adhesive suppliers .

We currently have over 300 employees including 8 engineers, all of them are participate in the composite materials development more than 10 years . Our factory is ISO9001:2008 certified in quality management systems, ISO14001 :2004 certified in environmental management systems and SAS 18001 certified for Occupational Health and Safety and BSCI(Business Social Compliance Initiative) certified. Our products also have passed SGS, CE(attestation of European Union), and CTC(China Building Material Certification).

If you have any questions, contact me, please.

Contact: Kerry zhu

Whatsapp & WeChat : +86 130 4067 0248

Email : kerry@der-acp.com

You'll get my response within 24 hours.

You'll get my response within 24 hours.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminium is the main base material in aluminium composite panels. From the point of view of use, aluminium plays a role in strengthening the support of the aluminium composite panel and is in contact with the surrounding environment through the coating. Therefore, the choice of aluminium has a great influence on the quality of the aluminium composite panel.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Brushed acp sheet is a manufacturing process of repeatedly scraping out the lines of aluminum sheet with sandpaper, and its process is mainly divided into 3 parts: de-esterification, sand grinding, and water washing.