Brushed Aluminum Composite Panel

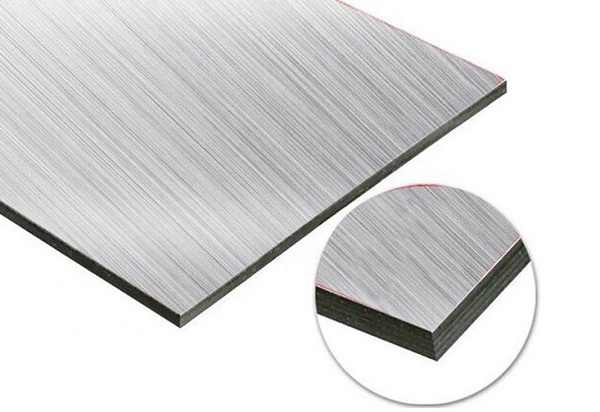

Aluminum composite panel is made of multi-layer materials, the upper and lower layer is high purity aluminum alloy panel, the middle is non-toxic low density polyethylene (PE) core panel, and its front side is also pasted with a protective film. For outdoor, the front side of the aluminum composite panel is coated with fluorocarbon resin (PVDF), and for indoor, the front side can be coated with non-fluorocarbon resin.

Brushed acp sheet is a manufacturing process of repeatedly scraping out the lines of aluminum sheet with sandpaper, and its process is mainly divided into 3 parts: de-esterification, sand grinding, and water washing.

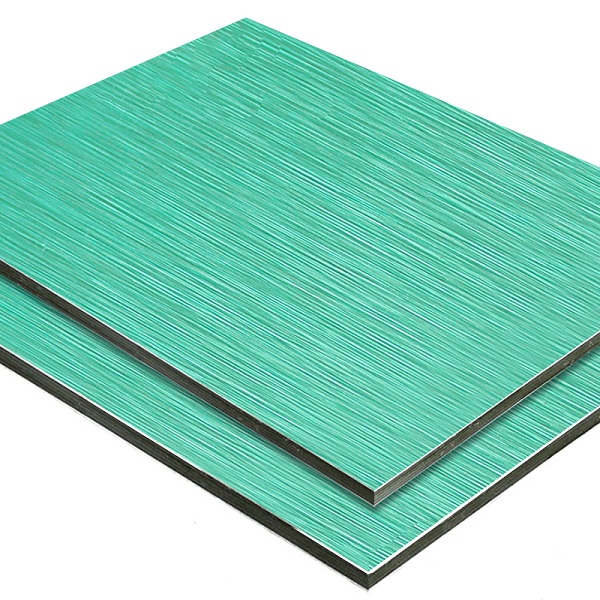

Brushed acp panel is a manufacturing process of repeatedly scraping out the lines of aluminum sheet with sandpaper, and its process is mainly divided into 3 parts: de-esterification, sand grinding, and washing. In the brushed aluminum composite panels process, the special skin technology after anodic treatment can make the surface of aluminum sheet generate a kind of skin layer containing the metal composition, clearly showing every fine silk trace, thus making the metal matte with a fine hair luster. More and more aluminum products are using the metal shell of the brushed metal process, to play a beautiful, anti-erosion role. This makes the product both stylish and technological. This is one of the reasons for the popularity of this process.

In the process of processing aluminum sheets under pressure, the sheet is forced through a mold under the action of an external force, and the cross-sectional area of the metal is compressed to obtain the required cross-sectional area shape and size in a technical process called aluminum sheet drawing. The tool that makes the aluminum sheet change its shape and size is called a drawing die.

Application

Wire drawing aluminum sheet is widely used in the fields of wire drawing aluminum composite panel acp , fireproof acp panel, aluminum photo frame, fine cabinet, fine doors and windows, veneer panel, signage, lighting, interior and exterior decoration, household appliances, luggage, gifts, furniture, consumer electronics, etc.

Pure aluminum plate: pure aluminum plate series commonly used code 1050, 1060, 1100. in all aluminum plate series pure aluminum plate series belongs to a series with the most aluminum content. The purity can reach more than 99.00%. Since it does not contain other technical elements, the production process is relatively single and the price is relatively cheap, so it is one of the most commonly used series in the conventional industry at present. Most of the series in circulation on the market are 1050 as well as 1060 series.

l You may also want to know about aluminum composite materials

|

Coating |

PE / PVDF/ FEVE/ NANO |

|

Core |

LDPE/Fireproof |

|

Length |

Customized |

|

Color |

Solid / Metallic / Marble / Wooden / Brush / Glossy/ Mirror, custom |

|

MOQ |

600 SQM each size per color |

|

Brand / OEM |

DERACP or Customized |

|

Delivery |

15 day after deposit received and color confirmed |

|

Payment Terms |

T/T / L/C / Western Union / Paypal |

|

Packing |

Wooden Package or bulk loading |

l About DERACP

DERACP found in 2000 ,we are specialized in manufacturing building materials, such as Aluminum Corrugated Composite Panel (ACCP) , Aluminum Composite Panel (ACP) ,Color coated Aluminum Coil etc.The factory located in Wenzhou, Zhejiang Province, China, all transportation options are convenience to the factory.It's easy to get to the airport and port. Our factory covers an area of 15,000 square meters , the warehouse covers an area of 5000 square meters and has six production lines. We have the best aluminum leather suppliers and adhesive suppliers .

We currently have over 300 employees including 8 engineers, all of them are participate in the composite materials development more than 10 years . Our factory is ISO9001:2008 certified in quality management systems, ISO14001 :2004 certified in environmental management systems and SAS 18001 certified for Occupational Health and Safety and BSCI(Business Social Compliance Initiative) certified. Our products also have passed SGS, CE(attestation of European Union), and CTC(China Building Material Certification).

If you have any questions, contact me, please.

Contact: Kerry zhu

Whatsapp & WeChat : +86 130 4067 0248

Email : kerry@der-acp.com

You'll get my response within 24 hours.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminium is the main base material in aluminium composite panels. From the point of view of use, aluminium plays a role in strengthening the support of the aluminium composite panel and is in contact with the surrounding environment through the coating. Therefore, the choice of aluminium has a great influence on the quality of the aluminium composite panel.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is made of multi-layer materials, the upper and lower layer is high purity aluminum alloy panel, the middle is non-toxic low density polyethylene (PE) core panel, and its front side is also pasted with a protective film. For outdoor, the front side of the aluminum composite panel is coated with fluorocarbon resin (PVDF), and for indoor, the front side can be coated with non-fluorocarbon resin.