Aluminum: The curtain Aluminum Composite Panel adopts other series of aluminum alloys whose material properties should meet the requirements of GB/T3880.2, 3××× series, 5××× series or better corrosion resistance and mechanical properties. The aluminum should be cleaned and chemically pretreated to remove oil, dirt and loose oxide layers naturally formed by contact with air and form a chemical conversion coating to facilitate aluminum and coating. Strong bonding of the core layer.

Coating: The fa?ade board coating material should be made of fluorocarbon resin with excellent weather resistance, and other materials with comparable or superior properties.

Note 1: At present, the most widely used polyvinylidene fluoride fluorocarbon resin (PVDF) with excellent weather resistance, but pure PVDF resin should not be directly coated on aluminum, but some other materials should be added to change its coating. The performance is the so-called 70% fluorocarbon resin.

Note 2: 70% fluorocarbon resin refers to 70% of the various raw materials used in the production of paint for aluminum-plastic panel coating. The final content of PVDF in the total coating of the ACP panel is about 25% to 45%, because there are pigments and other components in the paint and a primer coating of a non-fluorocarbon resin under the fluorocarbon resin coating.

Core material: The material properties of the raw materials used for ordinary curtain wall core materials should meet the requirements of GB11115, GB11116, GB/T15182 or other corresponding national or industry standards.

Note 1: The quality of the core material is closely related to the quality of the aluminum composite panel. Inferior waste plastics often contain a lot of harmful impurities and severely aged plastics, which is extremely unfavorable for the quality of ACM panels.

Note 2: Polyvinyl chloride is generally considered to be unsuitable as a core material because it is easily decomposed at high temperatures to produce strong toxic and corrosive substances.

Therefore, to take a long-term route, it is a good choice to choose aluminum composite panel.

Feel free to contact me if you have any question. My phone is 13627744758 (Wechat & Whatsapp)

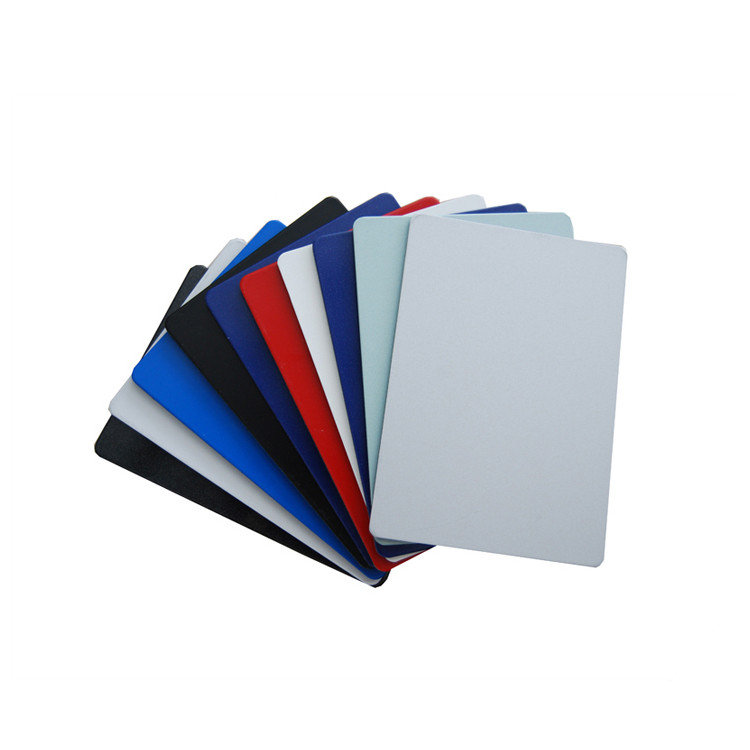

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminium is the main base material in aluminium composite panels. From the point of view of use, aluminium plays a role in strengthening the support of the aluminium composite panel and is in contact with the surrounding environment through the coating. Therefore, the choice of aluminium has a great influence on the quality of the aluminium composite panel.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is made of multi-layer materials, the upper and lower layer is high purity aluminum alloy panel, the middle is non-toxic low density polyethylene (PE) core panel, and its front side is also pasted with a protective film. For outdoor, the front side of the aluminum composite panel is coated with fluorocarbon resin (PVDF), and for indoor, the front side can be coated with non-fluorocarbon resin.