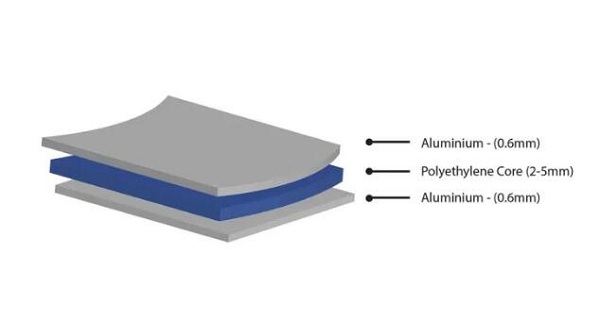

Aluminum composite pane acpl is made of multi-layer materials, the upper and lower layers are high-purity aluminum alloy panels, the middle is non-toxic low-density polyethylene (PE) core board, and a protective film is pasted on its front side. For outdoor, the front side of the aluminum composite panel sheet is coated with fluorocarbon resin (PVDF), while for indoor, the front side can be coated with non-fluorocarbon resin.

The unique properties of aluminum composite panels itself determine its wide range of uses: it can be used for building facades, curtain wall panels, renovation of old buildings, indoor wall and ceiling decoration, advertising signs, display stands, and purification and dust control projects. It is a new type of building decoration material.

Is aluminium composite panel a fireproof material Most of the aluminium composite panels on the market at present are fireproof materials. The fireproof grade of aluminium composite panels is B1, which does not belong to class A fireproof material, because there is generally a film pasted between the PE material inside the aluminium composite panels and the aluminium, and this film is generally combustible, so the aluminium composite panels are generally unable to reach the non-combustible class A fireproof material.

The fire rating of aluminium composite panels materials is several levels Aluminium composite panels belong to B1 level fireproof material. The fire rating of aluminium composite panels is determined by two indicators, which are the national mandatory standard GB8624 "Methods of grading the combustion performance of building materials" and GB/T17748 "Aluminium composite panels" national standard requirements. The grade of fireproof aluminium composite panels cannot be lower than B1, which is a flame-retardant building material. B1 grade flame-retardant building materials: flame-retardant class materials have a better flame retardant effect. It is difficult to start a fire in the air or under the action of high temperature, and it is not easy to spread quickly, and burning stops immediately when the fire source is removed. Fireproof aluminium composite panel (B1 level) testing indicators and requirements: (1) according to GB/T8625-88 for testing, the average remaining length of each group of test pieces ≥ 150mm, (the remaining length of any of the test pieces > 0), and the average smoke temperature peak of each test ≤ 200 ℃. (2) according to GB/T8626-88 for testing, flame tip height indicator <150mm, and do not allow the phenomenon of burning droplets igniting the filter paper. (3) Test according to GB/T8627-1999, smoke density rating (SDR) ≤ 75.

The fire rating of aluminium composite panels is determined by two indicators, which are the national compulsory standard GB8624 "burning performance grading method of building materials" and GB/T17748 "aluminium composite panels" national standard requirements.

China's building materials combustion performance grading as follows.

Class A: Non-combustible building materials

Class B1: Flame-retardant building materials

Class B2: Combustible building materials

Class B3: Flammable building materials

The grade of fire resistant aluminium composite panels should not be lower than B1.

l You may also want to know about aluminum composite materials

|

Coating |

PE / PVDF/ FEVE/ NANO |

|

Core |

LDPE/Fireproof |

|

Length |

Customized |

|

Color |

Solid / Metallic / Marble / Wooden / Brush / Glossy/ Mirror, custom |

|

MOQ |

600 SQM each size per color |

|

Brand / OEM |

DERACP or Customized |

|

Delivery |

15 day after deposit received and color confirmed |

|

Payment Terms |

T/T / L/C / Western Union / Paypal |

|

Packing |

Wooden Package or bulk loading |

l About DERACP --acp manufacturer

DERACP found in 2000 ,we are specialized in manufacturing building materials, such as Aluminum Corrugated Composite Panel (ACCP) , Aluminum Composite Panel (ACP) ,Color coated Aluminum Coil etc.The factory located in Wenzhou, Zhejiang Province, China, all transportation options are convenience to the factory.It's easy to get to the airport and port. Our factory covers an area of 15,000 square meters , the warehouse covers an area of 5000 square meters and has six production lines. We have the best aluminum leather suppliers and adhesive suppliers .

We currently have over 300 employees including 8 engineers, all of them are participate in the composite materials development more than 10 years . Our factory is ISO9001:2008 certified in quality management systems, ISO14001 :2004 certified in environmental management systems and SAS 18001 certified for Occupational Health and Safety and BSCI(Business Social Compliance Initiative) certified. Our products also have passed SGS, CE(attestation of European Union), and CTC(China Building Material Certification).

If you have any questions, contact me, please.

Contact: Kerry zhu

Whatsapp & WeChat : +86 130 4067 0248

Email : kerry@der-acp.com

You'll get my response within 24 hours.

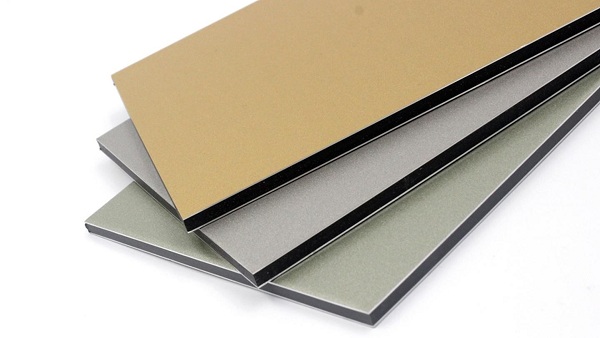

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminium is the main base material in aluminium composite panels. From the point of view of use, aluminium plays a role in strengthening the support of the aluminium composite panel and is in contact with the surrounding environment through the coating. Therefore, the choice of aluminium has a great influence on the quality of the aluminium composite panel.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is made of multi-layer materials, the upper and lower layer is high purity aluminum alloy panel, the middle is non-toxic low density polyethylene (PE) core panel, and its front side is also pasted with a protective film. For outdoor, the front side of the aluminum composite panel is coated with fluorocarbon resin (PVDF), and for indoor, the front side can be coated with non-fluorocarbon resin.