Breakable core and unbreakable core in aluminum composite panel sheet

Breakable is also called raw; unbreakable core is called clinker.

In the construction project, people often use plastic sheet raw material and clinker, so what is the difference between aluminum plastic sheet raw material and clinker?

Let me briefly explain that the core material of the aluminum composite panel is based on the requirement of non-toxic PE core material, but in order to reduce costs, many manufacturers use the so-called raw material, the raw material core material aluminum composite panel acm and the clinker aluminum composite panel The distinction is still great. The following analyzes from 5 aspects:

1. Resilience.

Due to the poor toughness of the raw material, the raw material aluminum composite panel is easy to break, and the clinker aluminum composite panel has good toughness and is not easy to be broken.

2. Processing aspects.

When processing aluminum-plastic panels, raw materials may cost more cutter heads. After all, there are impurities.

3. Advantages and disadvantages.

When the aluminum skin is thick, the advantages and disadvantages of the two core materials will not appear on the surface of the construction effect.

Otherwise, when the aluminum skin is thin, the finished aluminum composite panel of the raw material core material often has some small protrusions, and the flatness is not good.

4. Detection of core material particles.

According to the detection of specific gravity, the particles are placed in the water, and the clinker floating on it, otherwise the raw meal.

5. The price of aluminum-plastic panels.

Due to the price difference of raw materials, raw aluminum-plastic panels are much cheaper than clinker aluminum-plastic panels.

In view of the above reasons, when buying aluminum-plastic panels, do not just look at the price, but also the quality. The cheaper price must be the raw aluminum-plastic panels. The raw aluminum-plastic panels are not only insecure in quality, but also in terms of service life. There is no guarantee, and various situations will occur after construction.

1. Application of fluorocarbon resin

As we all know, fluorocarbon coatings with super weather resistance, durability, corrosion resistance, and excellent adhesion resistance are widely used on outdoor building curtain walls. Aluminum composite board for curtain walls require the fluorocarbon resin content in the fluorocarbon paint. (Polyvinylidene fluoride) must be equal to or higher than 70%. Only in this way can the quality of the fluorocarbon coating and the long-term beauty of the building exterior be ensured.

2. The difference of PE core material in acp

Aluminum-plastic composite panels generally use high-pressure low-density polyethylene resin (LDPE) as the core material. Its mechanical properties, anti-aging performance, moderate toughness and bending performance have a strong impact on the overall performance of aluminum-plastic composite panels (especially ACM for curtain walls). Has a major impact.

In the process of use, aluminum-plastic composite materials are required to have good processing properties such as folding, bending, and slotting. Therefore, when selecting PE core materials, the requirements for PE should be stable performance, moderate melt index, and fracture extension. Raw material with better growth rate. According to different product ranges, the melt index is generally required to be 0.4ˉ2.0g/10min, and the appropriate aluminum-plastic panel for curtain wall is 0.4ˉ0.8g/10min, and the elongation at break should be greater than 400%. Because the LDPE core material with a suitable melt index is used, the aluminum-plastic composite panel acp has good surface strength and high flatness. A larger area can be used in engineering design. For example, LDPE with an excessive melt index is not easy to process. Shaped, and the strength of the formed sheet is also low, which can only be used in smaller areas in engineering design. In the production process, if LDPE with a large melting index is selected, it is easy to over-soften under high temperature conditions, and sufficient composite pressure cannot be ensured. Only the method of lowering the process temperature and the selection of low-melting polymer adhesive films can be used. It will lead to a decrease in the adhesion between aluminum and plastic-peel strength, so some products reduce the production temperature in order to ensure the flatness of their surface, resulting in the sacrifice of peel strength is extremely inappropriate. Experiments have proved that the seasonal temperature difference in actual use of aluminum composite panel for curtain walls can reach -30° to more than 60°. Such a large temperature difference is likely to cause the aluminum-plastic composite panel to gradually change. If the initial peel strength is not high or the PE core material is softened If the point is too low, the application of aluminum-plastic composite panels on the curtain wall will cause major quality hazards.

At present, there is a large amount of recycled materials used in the production of aluminum composite panels acp. Most of these recycled materials have been recycled for many times. The internal structure of the materials is damaged and the molecules are degraded seriously. Generally, the melting index of this kind of recycled material is unstable, and the elongation at break is about 100%. Therefore, the processed plate has poor flatness, has many small pits on the surface, and the plate is easy to break. This kind of recycled materials can only be used for aluminum-plastic panels for identification signs, and is not suitable for the production of aluminum composite panel for curtain walls.

In the production process of aluminum plastic panel for curtain walls, LDPE should be selected according to the actual situation. Considering the environmental protection and recycling of materials, high-grade recycled PE can be used, or recycled PE can be mixed with new materials. The addition amount is generally not The performance of aluminum-plastic panels for curtain walls is limited. The performance index requirements of LDPE of aluminum-plastic panels for curtain walls are generally 0.925-0.945, the melt index is 0.4ˉ0.8g/10min, and the elongation at break should be greater than 400%.

l You may also want to know about aluminum composite materials

|

Coating |

PE / PVDF/ FEVE/ NANO |

|

Core |

LDPE/Fireproof |

|

Length |

Customized |

|

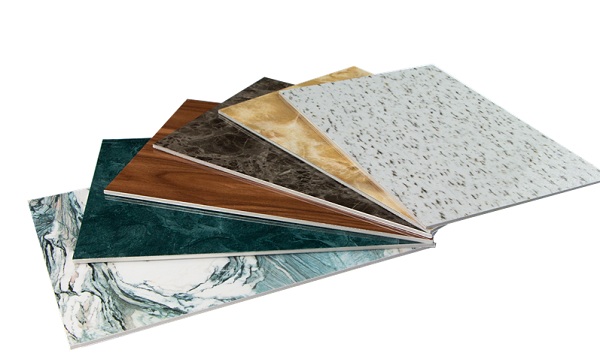

Color |

Solid / Metallic / Marble / Wooden / Brush / Glossy/ Mirror, custom |

|

MOQ |

600 SQM each size per color |

|

Brand / OEM |

DERACP or Customized |

|

Delivery |

15 day after deposit received and color confirmed |

|

Payment Terms |

T/T / L/C / Western Union / Paypal |

|

Packing |

Wooden Package or bulk loading |

l About DERACP

DERACP found in 2000 ,we are specialized in manufacturing building materials, such as Aluminum Corrugated Composite Panel (ACCP) , Aluminum Composite Panel (ACP) ,Color coated Aluminum Coil etc.The factory located in Wenzhou, Zhejiang Province, China, all transportation options are convenience to the factory.It's easy to get to the airport and port. Our factory covers an area of 15,000 square meters , the warehouse covers an area of 5000 square meters and has six production lines. We have the best aluminum leather suppliers and adhesive suppliers .

We currently have over 300 employees including 8 engineers, all of them are participate in the composite materials development more than 10 years . Our factory is ISO9001:2008 certified in quality management systems, ISO14001 :2004 certified in environmental management systems and SAS 18001 certified for Occupational Health and Safety and BSCI(Business Social Compliance Initiative) certified. Our products also have passed SGS, CE(attestation of European Union), and CTC(China Building Material Certification).

If you have any questions, contact me, please.

Contact: Kerry zhu

Whatsapp & WeChat : +86 130 4067 0248

Email : kerry@der-acp.com

You'll get my response within 24 hours.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminium is the main base material in aluminium composite panels. From the point of view of use, aluminium plays a role in strengthening the support of the aluminium composite panel and is in contact with the surrounding environment through the coating. Therefore, the choice of aluminium has a great influence on the quality of the aluminium composite panel.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

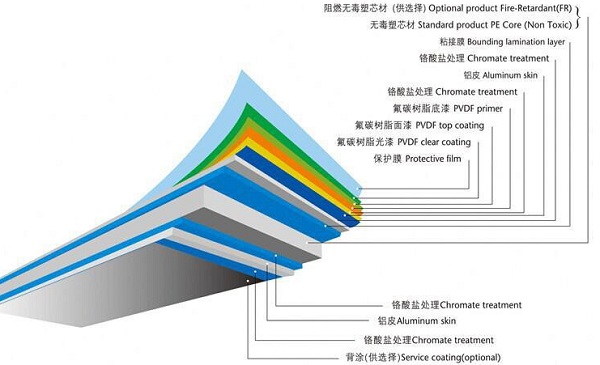

Aluminum composite panel is made of multi-layer materials, the upper and lower layer is high purity aluminum alloy panel, the middle is non-toxic low density polyethylene (PE) core panel, and its front side is also pasted with a protective film. For outdoor, the front side of the aluminum composite panel is coated with fluorocarbon resin (PVDF), and for indoor, the front side can be coated with non-fluorocarbon resin.