Core Tips: The performance of fireproof ACP should meet the following requirements

1. Surface pencil hardness

The surface pencil hardness of the aluminum composite panel should be greater than or equal to H.

2. Coating gloss deviation

The coating gloss deviation of ACP sheet should be less than or equal to 10.

3. Coating flexibility / T

The coating flexibility/T of the aluminum composite panel should be less than or equal to 2.

4. Coating adhesion a / grade

The adhesion of the ACP sheet should be 0, and the arbitration method should be grade 1.

5. Impact resistance

The impact resistance of the fireproof ACP should be greater than or equal to 50kg.cm.

6. Coating wear resistance

The wear resistance of the fireproof ACP / L / um should be greater than or equal to 5.

7. Coating acid resistance

The aluminum composite panel coating has no change in acid resistance.

8. Oil resistance of the coating

The oil resistance of panel coating should be unchanged.

9. Coatings and other alkali resistance

The ACP sheet coating should have no abnormality such as bubbling, bulging and chalking, and the color difference ΔE≤2.

10. Coatings resistant to nitrate

The coating should have no abnormality such as bubbling, bulging and chalking, and the color difference ΔE≤5.

11. Coating solvent resistance

The solvent resistance of the coating should not be exposed.

12. Coating stain resistance

Aluminum composite panel coating stain resistance /% should be less than or equal to 5.

13. Resistance to artificial weathering

The artificial weathering resistance of the panel should be mainly manifested in the color difference △E should be less than or equal to 4.0, the loss level/level should be not inferior to 2, and the other aging performance/level should be 0.

14 salt spray resistance

The salt spray resistance of panels should be no less than Grade 1.

15 bending strength

The bending strength should be greater than or equal to 120b / MPa.

16. Flexural modulus / MPa

The bending elastic modulus of the aluminum composite panel / MPa should be greater than or equal to 3.03104.

17. Through resistance / kN

The penetration resistance / kN should be greater than or equal to 8.0.

18. Shear strength / MPa

Aluminum composite panel shear strength / MPa should be greater than or equal to 25.0.

19. Peel strength / (N / mm)

The average peeling strength of the panel / (N / mm) should be greater than or equal to 140, the minimum value should be greater than 125.

20. Temperature difference performance

The temperature difference performance of the panel should be unchanged from the appearance, and the peel strength reduction rate/% should be less than or equal to 10. The coating adhesion should be a/grade, the cross-cut method should be 0, and the arbitration method should be level 1.

21. Thermal expansion coefficient / °C-1

Aluminum composite panel thermal expansion coefficient / °C-1 ≤ 3.00310-5.

22. Heat distortion temperature / °C

Aluminum composite panel heat distortion temperature / ° C ≥ 95

23. Hot water resistance

There should be no abnormality in the hot water resistance of the aluminum composite panel.

24. Combustion performance

Aluminum composite panel burning performance should be not lower than A2

Feel free to contact me if you have any question. My phone is 13627744758 (Wechat & Whatsapp)

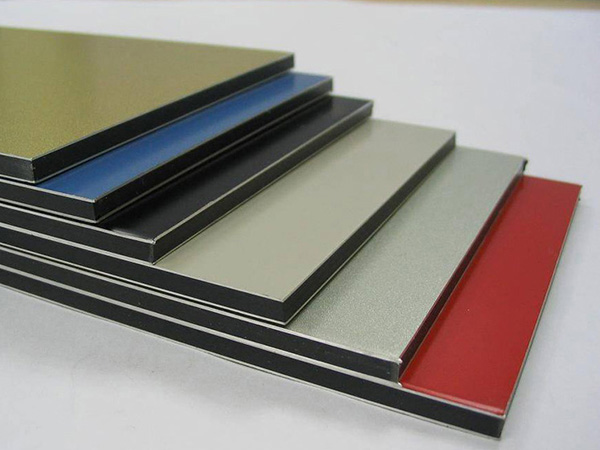

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminium is the main base material in aluminium composite panels. From the point of view of use, aluminium plays a role in strengthening the support of the aluminium composite panel and is in contact with the surrounding environment through the coating. Therefore, the choice of aluminium has a great influence on the quality of the aluminium composite panel.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is made of multi-layer materials, the upper and lower layer is high purity aluminum alloy panel, the middle is non-toxic low density polyethylene (PE) core panel, and its front side is also pasted with a protective film. For outdoor, the front side of the aluminum composite panel is coated with fluorocarbon resin (PVDF), and for indoor, the front side can be coated with non-fluorocarbon resin.