If you are interested in our products, plz feel free to contact me at +8613627744758 (Wechat & Whatsapp & Phone)

1. Observing - Aluminum composite material panels are without ripples, bubblings, scratches and smoothy on the surface are good quality.

2. Measuring - Measuring the aluminum composite material (acm) if it meets the international requirements, with the interior wall panel in 3mm, the exterior wall panel in 4mm or above, and the thickness of the aluminum skin in 0.5mm.

3. Bending - If it's easily broken then it's not polyethylene core or made of fake polyethylene core.

4. Burning - The real polyethylene core can be burnt to ash. However, tere will be impurities leftover for fake poltethylene core.

5.Slotting - When cutting the grooves, check if the surface is broken.

6.Chemical reaction - Butanone can be used for testing the fluorocarbon coating on the exterior wall panel. Drop some xylene on the surface, 5 minutes later, wipe off and check if there is dissolved.

7. Requesting - Ask the supplier to provide manufacturer quality inspection report, warranty book, ISO-9002 international quality certification etc. Those who process these certificates are qualified aluminum composite panel supplier. They can guarantee the quality of panels.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminium is the main base material in aluminium composite panels. From the point of view of use, aluminium plays a role in strengthening the support of the aluminium composite panel and is in contact with the surrounding environment through the coating. Therefore, the choice of aluminium has a great influence on the quality of the aluminium composite panel.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

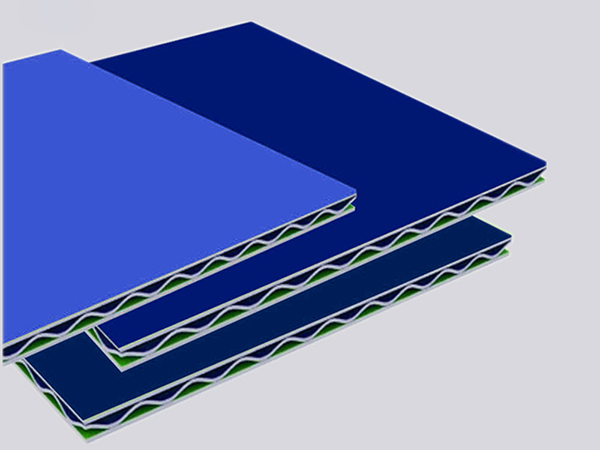

Aluminum composite panel is made of multi-layer materials, the upper and lower layer is high purity aluminum alloy panel, the middle is non-toxic low density polyethylene (PE) core panel, and its front side is also pasted with a protective film. For outdoor, the front side of the aluminum composite panel is coated with fluorocarbon resin (PVDF), and for indoor, the front side can be coated with non-fluorocarbon resin.