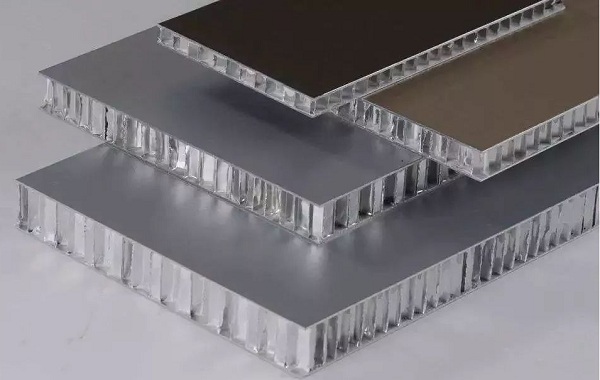

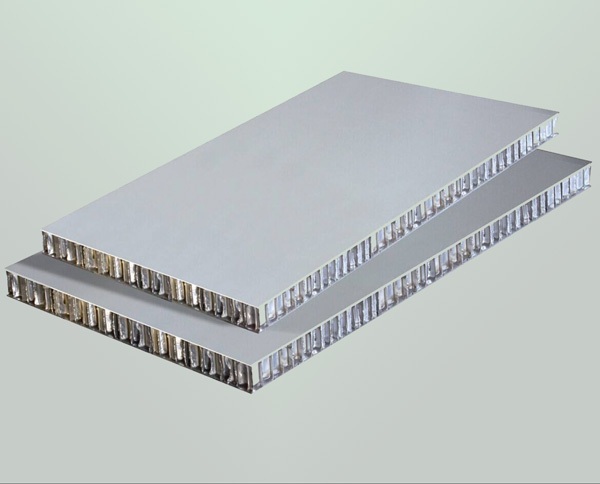

Aluminium honeycomb panels have the advantages of being lightweight, soundproof, heat insulating, fireproof, environmentally friendly, unbreakable, rigid and non-deformable. The high flatness of the panel surface and the high strength aluminium honeycomb core between the two layers of aluminium panels form the ideal panel with high flatness and not easily deformed. Surface treatment techniques include polyester spraying, fluorocarbon spraying, roller coating, thermal transfer printing, etc.

The difference between aluminium honeycomb panels and aluminium composite panels

The uses of aluminium honeycomb panels are generally as follows: building curtain wall exterior wall pegboard, interior decoration, billboards, ship building, aviation manufacturing, indoor partitions, buses, high speed rail, metro and rail vehicles, etc. In addition, for the modern demanding modern home industry, using aluminium honeycomb panels as processing material for furniture is a good choice of material these years, which can be a completely non-toxic green material, allowing furniture manufacturers to eliminate unnecessary environmental procedures when processing.

Aluminium composite panels are a new type of decorative material with many incomparable advantages compared to other decorative materials. The reason for this is, on the one hand, because aluminium composite panels are a composite material, through the composite can obtain many new properties that are not available in the original component materials. On the other hand, aluminium composite panels are a kind of high technology products, both production and application, all contain a high technical content. Many advanced processes are used in the production, such as the roll coating process and the continuous thermal compounding process, to ensure that the performance of the material is given full play.

Main characteristics of aluminium-plastic composite panels

1. Small quality: aluminium-plastic composite panels are made of aluminium and a relatively small density of plastic core material composite, so compared with aluminium (or other metals) with the same rigidity or thickness, its mass is smaller; compared with glass and stone, the mass is much smaller, which can reduce the load of the building structure.

2. Good rigidity: aluminium-plastic panels cleverly use the mechanics of the I-beam structure, cleverly give its unique mechanical properties, plus aluminium-plastic panels are in high temperature conditions to achieve composite, and in the whole process of processing two layers of aluminium panels in a certain state of tension, when forming and cooling, because the upper and lower symmetrical aluminium panels and the core plate in the shrinkage rate difference, the formation of a stable internal stress and good rigidity of the plate. Compared with single-layer aluminium sheet, its elasticity limit is larger, not easy to produce deformation, in the natural state without too much external force, can maintain a good flat performance for a long time.

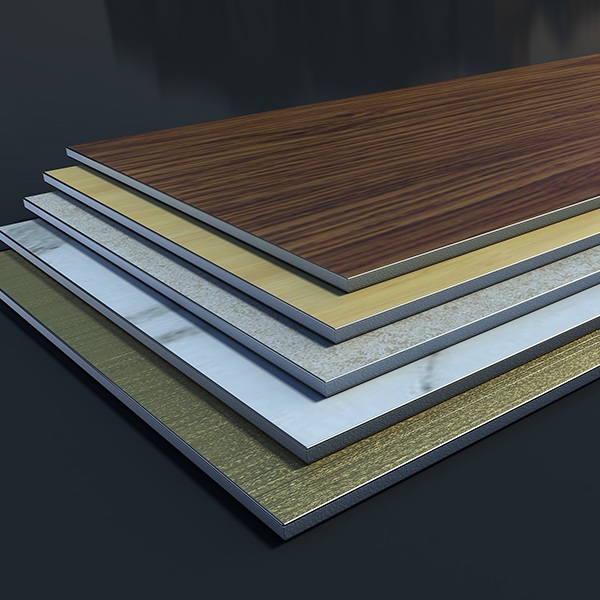

3. Colourful and decorative: the coated surface of aluminium composite panels can be made into a wide variety of colours and carry out pattern designs that match all uses. In addition, it can also be used to simulate the pattern of granite, wood grain and metal using photocopying technology, providing a single colour that is not available, with a precise texture and high quality pattern design.

4. Surface flatness bet: aluminium composite panels are produced by continuous thermal composite production process, so compared with single material metal panels, its surface flatness is high, especially for large size panels is more obvious. Used for building decoration, it has a flat appearance that is all in one.

5. Good durability: aluminium-plastic composite panels use metal and core material thermal composite technology, solid bonding, its surface coating according to the use of different environments using different coatings, generally using three types of coatings, namely fluorocarbon coatings, polyester coatings, acrylic coatings, including fluorocarbon coatings have excellent outdoor weather resistance, mostly used in curtain wall decoration and characteristics of the occasion, experimental research shows that in the harsh outdoor environment can be used for 20 years More than.

6. Good processability: aluminium-plastic composite panels are made of aluminium and plastic composite, easy to cut, punching, slotting, bending and other processing, available aluminium or wood special processing equipment for processing. Therefore, not only can be processed in the production plant, simple composite panels can be processed on site.

7. In the aluminium composite panel series, the fireproof aluminium composite panel adopts a newly developed core material, which is filled with non-combustible inorganic filler, so the improvement of fireproof performance has made a leap and can reach B1 level flame retardant and A2 level non-combustible fireproof standard, which can meet the fireproof requirements in the building regulations.

8. Good cost characteristics: The production of aluminium-plastic composite panels adopts pre-painted continuous coating as well as continuous thermal compounding process of metal and core materials, compared with general metal veneer, it has high production efficiency and low raw material cost, which is a material with good cost characteristics.

9. Good environmental compatibility: both aluminium and plastic cores in the discarded aluminium-plastic composite panels can be 100% recycled, with low environmental load. In addition, the curtain wall aluminium composite panels and outdoor decorative aluminium composite panels use fluorocarbon coating, the products have high durability and low daily maintenance costs, reducing the whole life cycle costs.

10. Versatility

If classified according to the scope of use and application, aluminium composite panels can be divided into indoor and outdoor aluminium composite panels, indoor aluminium composite panels are also known as internal wall panels, the surface of which is generally coated with rolled polyester resin, while outdoor aluminium composite panels are also known as external wall panels or curtain wall panels. It is resistant to sun, rain and bad weather.

l You may also want to know about aluminum composite materials from DERACP

|

Coating |

PE / PVDF/ FEVE/ NANO |

|

Core |

LDPE/Fireproof |

|

Length |

Customized |

|

Color |

Solid / Metallic / Marble / Wooden / Brush / Glossy/ Mirror, custom |

|

MOQ |

600 SQM each size per color |

|

Brand / OEM |

DERACP or Customized |

|

Delivery |

15 day after deposit received and color confirmed |

|

Payment Terms |

T/T / L/C / Western Union / Paypal |

|

Packing |

Wooden Package or bulk loading |

l About DERACP

DERACP found in 2000 ,we are specialized in manufacturing building materials, such as Aluminum Corrugated Composite Panel (ACCP) , Aluminum Composite Panel (ACP) ,Color coated Aluminum Coil etc.The factory located in Wenzhou, Zhejiang Province, China, all transportation options are convenience to the factory.It's easy to get to the airport and port. Our factory covers an area of 15,000 square meters , the warehouse covers an area of 5000 square meters and has six production lines. We have the best aluminum leather suppliers and adhesive suppliers .

We currently have over 300 employees including 8 engineers, all of them are participate in the composite materials development more than 10 years . Our factory is ISO9001:2008 certified in quality management systems, ISO14001 :2004 certified in environmental management systems and SAS 18001 certified for Occupational Health and Safety and BSCI(Business Social Compliance Initiative) certified. Our products also have passed SGS, CE(attestation of European Union), and CTC(China Building Material Certification).

If you have any questions, contact me, please.

Contact: Kerry zhu

Email : kerry@der-acp.com

You'll get back to you within 24 hours.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminium is the main base material in aluminium composite panels. From the point of view of use, aluminium plays a role in strengthening the support of the aluminium composite panel and is in contact with the surrounding environment through the coating. Therefore, the choice of aluminium has a great influence on the quality of the aluminium composite panel.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is made of multi-layer materials, the upper and lower layer is high purity aluminum alloy panel, the middle is non-toxic low density polyethylene (PE) core panel, and its front side is also pasted with a protective film. For outdoor, the front side of the aluminum composite panel is coated with fluorocarbon resin (PVDF), and for indoor, the front side can be coated with non-fluorocarbon resin.