Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminium (acp ) wardrobe sliding doors and wood sliding doors have their own advantages and shortcomings, which also leaves consumers in a tangle of choice and at a loss. Is it better to have aluminium wardrobe sliding doors or wood plastic ones? Wood plastic sliding door wardrobe material is relatively soft, aluminum plastic sliding door wardrobe material is not easy to deformation, we can from these two sliding door wardrobe advantages and disadvantages of comprehensive analysis, at the same time to combine their own actual situation to choose a product to their satisfaction.

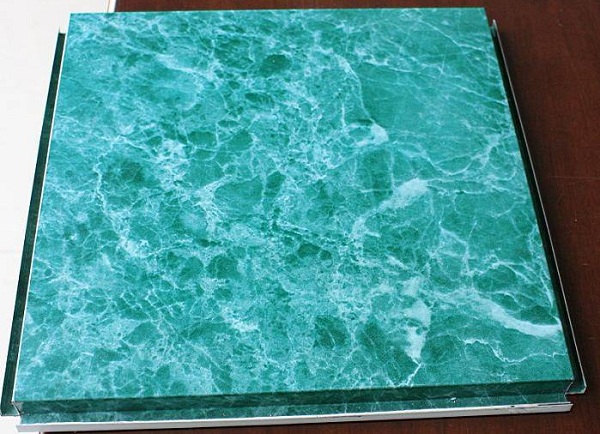

Wardrobe sliding door material wood plastic board and density board, which wood plastic board is not easy to deformation, but fragile. Density board is easy to deform, but the material is soft, impact resistant, easy and affordable. Aluminium composite panels can make sliding door wardrobes, aluminium composite materials are easier to clean and can be made in various patterns. Aluminium-plastic composite panels are composite materials made from chemically treated painted aluminium sheets (acp sheet) as the surface material and polyethylene plastic as the core material, processed on special aluminium-plastic panel production equipment.

Whether it is a sliding door wardrobe of aluminium-plastic or wood-plastic, the height of the sliding door wardrobe should preferably not exceed 2.1m, especially for solid wood, the width should be 35CM to 50CM, and the proportion should be coordinated. The upper part of the wood-plastic sliding door wardrobe is generally placed in cotton wool, quilts and other infrequently used items, more than 2.4m wardrobe is recommended to be divided into two parts, if the flat door is also designed to the top, open the wardrobe, will be at a glance, less mysterious. Wood plastic sliding door wardrobe will save interior space.

Features of wardrobe sliding door material WPC.

1, wood-plastic panels are also known as wood-plastic composite panels, wood-plastic composite panels of the main raw materials for sawdust, shredded wood, slag wood, thus making the hardness and toughness, can easily, including nails, grinding, drilling, paint, planing and so on and not easy to deformation, cracking and other problems, belong to the furniture decoration industry as well as the future of the construction industry green profiles.

2, the original name of the wood plastic board is PVC board / plastic wood board, wood plastic board advantages of many not easy to deformation, waterproof, flame retardant, mould, the only disadvantage is easy to damage in transit, installed on the door is relatively light no feel.

3, pure PVC wood plastic board does not participate in the appearance of waste wood colour yellow, poor wood plastic board although there is also PVC but not pure and add a variety of waste colour has particles of black or grey black dot.

4, good wood plastic board without any smell poor wood plastic board has a poor smell, wood plastic has a smell and waste has a great relationship.

Aluminum-plastic panels(acp) wardrobe sliding door features

1, super peel degree, aluminum composite panel using a new process, the most critical technical indicators of aluminum composite panel - peel strength, improved to an excellent state, so that the flatness of aluminum composite panel, weather resistance aspects of the performance are correspondingly improved.

2, the material is easy to process, aluminium composite panels, the weight of each square metre is only about 3.5-5.5 kg, so it can reduce the harm caused by the earthquake, and easy to carry, its superior construction only need simple woodworking tools can be completed cutting, cutting, planing edge, bending into arc, right angle of various shapes, can cooperate with the designer, make a variety of changes, easy installation, fast to reduce construction costs.

3, excellent fire performance, the middle of the aluminium composite panel is a flame retardant material PE plastic core, both sides are extremely difficult to burn aluminium layer. Therefore, it is a safe fireproof material that meets the fire resistance needs of building regulations.

4、Impact resistance, strong impact resistance, high toughness, bending does not damage the top coat, strong impact resistance, in windy and sandy areas also will not appear due to wind and sand caused by the breakage.

5, super weather resistance, due to the use of KYNAR-500 as the base material of the PVDF fluorocarbon paint acp , weather resistance have unique advantages, no matter in the hot sun or cold wind and snow are not damaged in the beautiful appearance, up to 20 years without fading.

6, uniform coating, colour diversity, after the application of chemical treatment and Henkel film technology, so that the adhesion between the paint and the aluminium composite panels acm is uniform, colour diversity, so that you can choose more space, to show your personalisation.

7, easy maintenance; aluminium composite panels, in terms of pollution resistance has been significantly improved. China's cities are more serious pollution, the use of a few years after the need for maintenance and cleaning, due to self-cleaning good, just use a neutral detergent and water can be, after cleaning so that the plate permanently as new.

l You may also want to know about aluminum composite materials from DERACP

|

Coating |

PE / PVDF/ FEVE/ NANO |

|

Core |

LDPE/Fireproof |

|

Length |

Customized |

|

Color |

Solid / Metallic / Marble / Wooden / Brush / Glossy/ Mirror, custom |

|

MOQ |

600 SQM each size per color |

|

Brand / OEM |

DERACP or Customized |

|

Delivery |

15 day after deposit received and color confirmed |

|

Payment Terms |

T/T / L/C / Western Union / Paypal |

|

Packing |

Wooden Package or bulk loading |

l About DERACP

DERACP found in 2000 ,we are specialized in manufacturing building materials, such as Aluminum Corrugated Composite Panel (ACCP) , Aluminum Composite Panel (ACP) ,Color coated Aluminum Coil etc.The factory located in Wenzhou, Zhejiang Province, China, all transportation options are convenience to the factory.It's easy to get to the airport and port. Our factory covers an area of 15,000 square meters , the warehouse covers an area of 5000 square meters and has six production lines. We have the best aluminum leather suppliers and adhesive suppliers .

We currently have over 300 employees including 8 engineers, all of them are participate in the composite materials development more than 10 years . Our factory is ISO9001:2008 certified in quality management systems, ISO14001 :2004 certified in environmental management systems and SAS 18001 certified for Occupational Health and Safety and BSCI(Business Social Compliance Initiative) certified. Our products also have passed SGS, CE(attestation of European Union), and CTC(China Building Material Certification).

If you have any questions, contact me, please.

Contact: Kerry zhu

Whatsapp & WeChat : +86 130 4067 0248

Email : kerry@der-acp.com

You'll get my response within 24 hours.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminium composite panels are made from multiple layers of material, with a high purity aluminium alloy panel on top and bottom and a non-toxic low density polyethylene (PE) core panel in the middle, with a protective film applied to the front. For exterior applications, the front of the aluminium composite panel is coated with a fluorocarbon resin (PVDF), while for interior applications, the front can be coated with a non-fluorocarbon resin.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminium composite panels are made from multiple layers of material, with a high purity aluminium alloy panel on top and bottom and a non-toxic low density polyethylene (PE) core panel in the middle, with a protective film applied to the front. For exterior applications, the front of the aluminium composite panel is coated with a fluorocarbon resin (PVDF), while for interior applications, the front can be coated with a non-fluorocarbon resin.

Aluminium composite panels are a new type of decorative material with many incomparable advantages compared to other decorative materials. The reason for this is, on the one hand, because aluminium composite panels are a composite material, through the composite can obtain many new properties that are not available in the original component materials. On the other hand, aluminium composite panels are a kind of high technology products, both production and application, all contain a high technical content