l What is PVC sheet

PVC sheet (PolyVinyl Chloride) is a sheet made of PVC with a honeycomb mesh structure in cross section.

PVC sheet accounts for the largest share of the building materials industry at 60%, followed by the packaging industry and several other small-scale applications. According to the degree of softness and hardness, it can be divided into soft PVC and hard PVC, and according to the production process, it can be divided into PVC crust foam board and PVC free foam board. On the basis of transparency and opacity it can be divided into PVC transparent board and PVC board. Hard PVC accounts for about 2/3 of the market and soft PVC accounts for 1/3.

According to the production process, it can be divided into PVC crust foam board and PVC free foam board.

Soft PVC is generally used for flooring, ceilings and the surface layer of leather, but its use is limited because soft PVC contains softener, which is easy to become brittle and not easy to preserve. Hard PVC does not contain softener, is flexible, easy to form, not easy to brittle, non-toxic and non-polluting, and has a long preservation time, so it has great value for development and application.

PVC foam board has the characteristics of anti-corrosion, moisture-proof, mold-proof, non-absorbent, drillable, sawable, planable, easy to thermoform, hot bending processing, etc. Therefore, it is widely used in furniture, cabinets, bath cabinets, exhibition shelves with boards, box cores, indoor and outdoor decoration, building materials, chemical and other fields with boards, advertising signs, printing, screen printing, spray painting, computer lettering, electronic instrument products packaging and other industries.

PVC hard plastic sheet has excellent corrosion resistance, insulation, and certain mechanical strength; it can be made into sulfuric acid (hydrochloric acid) tank (barrel box) after secondary processing; empty needle frame for medicine, chemical process frame; public bathroom water tank; template for processing products, decorative plate, exhaust duct, equipment lining and other kinds of shaped products and containers. It is the ideal choice material for chemical, building materials, decoration and other industries.

l What is aluminum composite panel

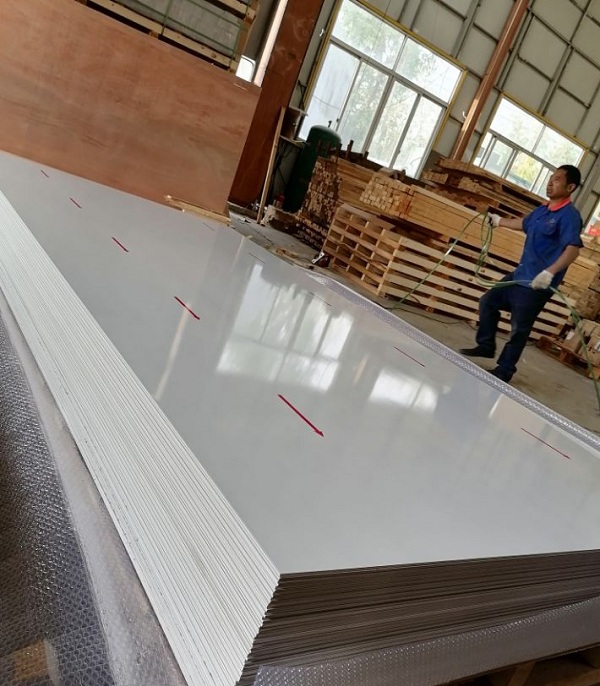

Aluminum composite panels is made of multi-layer materials, the upper and lower layers are high-purity aluminum alloy panels, the middle is non-toxic low-density polyethylene (PE) core board, and a protective film is pasted on its front side. For outdoor, the front side of the aluminum composite panel sheet is coated with fluorocarbon resin (PVDF), while for indoor, the front side can be coated with non-fluorocarbon resin.

The unique properties of aluminum composite panel acp sheet itself determine its wide range of uses: it can be used for building facades, curtain wall panels, renovation of old buildings, indoor wall and ceiling decoration, advertising signs, display stands, and purification and dust control projects. It is a new type of building decoration material.

l What is the difference between aluminum composite material l and PVC panel

1. Material: PVC board (PolyVinyl Chloride) is made of PVC with honeycomb mesh structure; aluminum composite board is made of multi-layer materials, the upper and lower layers are high purity aluminum alloy board, the middle is non-toxic low-density polyethylene (PE) core board, and the front side is also pasted with a protective film.

2. Process: PVC board can be divided into PVC crust foam board and PVC free foam board; aluminum composite materials panel is only one process.

3. Use: PVC, also known as decorative film, adhesive film, is a vacuum blister film, used in various types of panels for surface packaging, used in building materials, packaging, medicine and many other industries.

Aluminum composite panels can be used for building facades, curtain wall panels, renovation and refurbishment of old buildings, indoor wall and ceiling decoration, advertising signs, display stands, and purification and dustproof projects. It is a new type of building decoration material.

4. Characteristics: PVC foam board has the characteristics of anti-corrosion, moisture-proof, mold-proof, non-absorbent, drillable, sawable, planable, easy thermoforming, hot bending processing, etc.; aluminum cladding sheet is luxurious, colorful decorative, weather-resistant, corrosion-resistant, impact-resistant, fire-proof, moisture-proof, sound insulation, heat insulation, shock resistance, etc.; light weight, easy processing and molding, easy handling and installation, etc.

5. Specifications.

|

Hard PVC |

|

Product thickness: 0.8-30mm |

|

Product width: 1300mm, 1500mm |

|

Length: can be produced according to customer needs |

|

Laminate material: 2-60mm |

|

Product width: 1000mm×2000mm |

|

PVC transparent board |

|

Product thickness: 2-20mm |

|

Maximum product width: 1300mm |

|

Product length: 100-10000mm |

|

Recommended specification: 1300×2000mm |

|

PVC soft board roll |

|

Product thickness: 1-10mm |

|

Maximum product width: 1300mm |

|

Product length: unlimited |

|

Recommended specification: width 1300mm, weight 50kg/roll |

|

PVC welding rod: This product is designed for PVC transparent board construction welding, specifications are 1.5-3mm, 1000mm long, varieties are single, double, etc. |

|

Aluminum composite panel |

|

Thickness: 2mm, 3mm, 4mm, 5mm, 6mm |

|

Aluminum skin thickness: 0.1mm, 0.2mm, 0.3mm, 0.4mm, 0.5mm |

l Advantages and disadvantages of aluminum and PVC panels

Home furnishings of the kitchen and bathroom with these two materials with more, aluminum composite panels are generally in the aluminum buckle plate after the ceiling with exposed water and other aesthetic impact of the pipe with aluminum composite panels to make up for the defects of the aluminum buckle plate to achieve beautiful results, aluminum composite panels used in outdoor walls and outdoor storefront decoration more, because its construction process is more complex (mainly by the plate bottom, all with universal glue and other glues bonding), more difficult High (because to use glue, the climate, construction conditions, adhesive good or bad, construction workers level and other requirements), more expensive.

Indoor ceiling is used in aluminum and PVC panels, the main difference between the two is the new material and the old material, the difference in grade, and the difference in price, of course, aluminum panels are relatively more expensive. Specific differences are.

1, aluminum buckle plate mainly with light steel as the keel, PVC main wood keel as the framework

2, aluminum buckle plate used in home furnishing main specifications for 300 * 300 square, PVC is a long strip of width is mainly 10CM, 20CM and several

3, aluminum buckle plate life longer than 30 years (thickness to reach the national standard of more than 3, the lowest is the laminate) or more, PVC can also reach more than ten years (thickness, hardness has to reach)

4, aluminum buckle plate on the heavier moisture, soot larger rooms, corrosion resistance than PVC

5, aluminum buckle plate relative to PVC texture to be much stronger, but also the popular trend

6, aesthetically better

In general, aluminum buckle plate than PVC to be good, but the price is also higher, and then fine is the classification of the two materials, such as aluminum buckle plate has standard 7, standard 8, material spraying, roller coating, lamination, brushed stainless steel, etc., PVC also has a variety of patterns and imitation aluminum buckle plate style, but also thick Pu, hardness size and other distinctions.

Plus one is the upgrade of aluminum buckle plate is integrated ceiling, the brand is also more; PVC upgrade called plastic steel plate is a higher hardness

l which is better , PVC sheet and aluminum composite panel acp

Image wall material Cladding Aluminum composite panel

Aluminum-plastic sheet is a composite material processed on special aluminum-plastic sheet production equipment with chemically treated painted aluminum sheet as the surface material and polyethylene plastic as the core material. The aluminum composite panel itself has unique properties that determine its wide range of uses. It can be used for building exterior curtain wall panels, LOGO walls, old building renovation back to new, indoor wall and ceiling decoration, advertising signs, display stands, and purification and dustproof projects. Aluminum composite panel has been used in large quantities in China and is a new type of building decoration material. The thickness of acp sheet can be divided into three specifications: 1mm, 3mm and 4mm.

Characteristics of aluminum composite panel: Aluminum composite panel is a good material that is easy to process and shape. It has strong bending, good flatness, stable quality, high resistance to deflection, high sound insulation and fire prevention, light and bright, high temperature resistance, weathering resistance, decay resistance, abrasion resistance, and not easy to stain. Aluminum composite panel can be cut, cut, slotted, band sawed, drilled, processed and countersunk, also cold bent, cold folded, cold rolled, riveted, screwed or glued and bonded, etc.

Image wall material PVC board

PVC board is made of rigid polyvinyl chloride, which is waterproof, moisture-proof and moth-proof, and contains flame retardant materials, so it is safe to use. According to the production process and PVC foam board can be divided into PVC skin foam board and PVC free foam board, PVC skin foam board surface hardness is very high, it is difficult to produce scratches, widely used in advertising industry, is widely used in store, elevators, walls, ceilings, color pillars, counters and other places decorative and furniture, advertising carving, display windows, vehicles and ships partitions, etc.. Specification

PVC sheet is characterized by a flat and beautiful surface, light weight, flame retardant, moisture resistant, sound insulation, heat insulation, corrosion resistant, non-deformable, easy to cut, good weather resistance, high rigidity and strength, acid and alkali resistant, water immersion and easy to clean, etc.

According to the characteristics to choose it! The relative aluminum-plastic is a little better.

l You may also want to know:

|

Coating |

PE / PVDF/ FEVE/ NANO |

|

Core |

LDPE/Fireproof |

|

Length |

Customized |

|

Color |

Solid / Metallic / Marble / Wooden / Brush / Glossy/ Mirror, custom |

|

MOQ |

600 SQM each size per color |

|

Brand / OEM |

DERACP or Customized |

|

Delivery |

15 day after deposit received and color confirmed |

|

Payment Terms |

T/T / L/C / Western Union / Paypal |

|

Packing |

Wooden Package or bulk loading |

l About DERACP ---acp manufacturer

DERACP found in 2000 ,we are specialized in manufacturing building materials, such as Aluminum Corrugated Composite Panel (ACCP) , Aluminum Composite Panel (ACP) ,Color coated Aluminum Coil etc.The factory located in Wenzhou, Zhejiang Province, China, all transportation options are convenience to the factory.It's easy to get to the airport and port. Our factory covers an area of 15,000 square meters , the warehouse covers an area of 5000 square meters and has six production lines. We have the best aluminum leather suppliers and adhesive suppliers .

We currently have over 300 employees including 8 engineers, all of them are participate in the composite materials development more than 10 years . Our factory is ISO9001:2008 certified in quality management systems, ISO14001 :2004 certified in environmental management systems and SAS 18001 certified for Occupational Health and Safety and BSCI(Business Social Compliance Initiative) certified. Our products also have passed SGS, CE(attestation of European Union), and CTC(China Building Material Certification).

If you have any questions, contact me, please.

Contact: Kerry zhu

Whatsapp & WeChat : +86 130 4067 0248

Email : kerry@der-acp.com

You'll get my response within 24 hours.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminium is the main base material in aluminium composite panels. From the point of view of use, aluminium plays a role in strengthening the support of the aluminium composite panel and is in contact with the surrounding environment through the coating. Therefore, the choice of aluminium has a great influence on the quality of the aluminium composite panel.

Aluminum composite panel is a new type of building decoration material with the advantages of light quality, good stiffness, smooth surface, rich and colorful, convenient construction, etc. It is widely used in curtain wall, indoor and outdoor decoration and advertising signage, etc. It is an important decoration material reflecting modern architecture and decoration style.

Aluminum composite panel is made of multi-layer materials, the upper and lower layer is high purity aluminum alloy panel, the middle is non-toxic low density polyethylene (PE) core panel, and its front side is also pasted with a protective film. For outdoor, the front side of the aluminum composite panel is coated with fluorocarbon resin (PVDF), and for indoor, the front side can be coated with non-fluorocarbon resin.